The European Expert and Technical Support Centre on Friction and Wear

We are the European Expert and Technical Support Centre on Friction and Wear of the Falex group.

We assist you with Quality, Knowledge, and Partner Solutions in our field of expertise.

We achieve this by offering Testing Instruments, Lab Testing Services, and Technical Support.

1. TEST PROJECTS

1a. Standard Tests

- When you need to measure friction and wear properties of your materials

- When you want a reliable provider for Quality Control tests – ASTM, DIN, ISO, CEC

1b. Custom test design

- Procedures and test method support for your product development, quality control or troubleshooting needs

- When you’re looking for new insights into your product’s performance

- When you need an expert’s opinion on friction, wear and surface technology issues

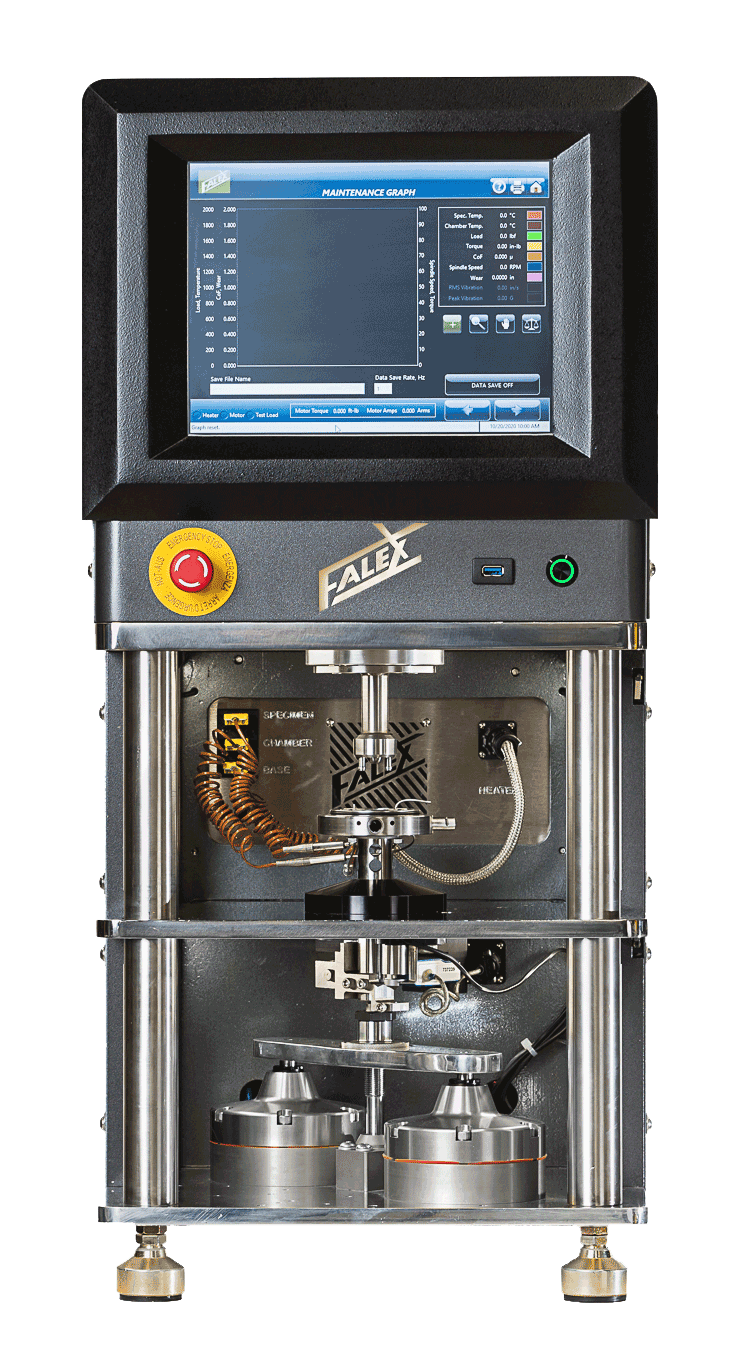

2. INSTRUMENT SALES

- Range of Instruments available delivering reliable and precise testing results

- Deliver the knowledge and expertise to ensure customers receive the right tribological

solution - For further information contact us.

3. TECHNICAL SUPPORT

- Continuous support : preventive maintenance and calibration contracts

- On-site diagnostic visits and repairs

- Training on test equipment and standard test methods

See also www.FactLabs.org

www.FactLabs.org

FACT Materials Selection Innovation Services Project has received funding from the European Union’s Horizon 2020 SME Instrument programme under Phase-1 grant agreement No 816766

Contact us to discuss your needs.

We’re always here to help. If you’re interested in any of our services please give us a call or fill out the contact form and we’ll assist in any way we can.